Scissor grab hanger / pincer grab hanger

An einer fest montierten Laufschiene im Bienenhaus oder am überdachten Freiständer mit einem Seilzug als Hebeeinrichtung.

An einer elektrisch betriebenen Seilwinde (Auf Anfrage)

- At the electric winch with pulley

- The pulley halves the pulling speed and reduces the installation height under the winch

Bestellung:

Mit oder ohne Hebeeinrichtung

Verfügbare Hebeeinrichtungen:

- Seilzug (Übersetzung 4/1)

- Elektroseilwinde auf Anfrage

Download PDF:

Product video: Rope hoist / gripper in the beehive

Customer video: Rope hoist / scissor grab hanger in the beehive

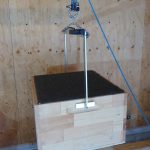

Pos. 13. tension beam hanger with scissor grab and cable pull transmission 4/1 To the store

- Wire rope hoist With switchable backstop Lifting height 1 metre.

- Tension beam: Individually adjustable clamping height per chain link, according to the frame stack height (max 1.0 metre).

- Scissor grabs: Adjustable to all common hive sizes. Each frame, even the entire hive, can be lifted and transported. The prerequisite is a space between the hives of at least 30mm.

- To order: Indication of frame length and width incl. handles.

- Scissor grabs on the tension beam hanger

- Tension beam hanger on wire rope hoist and running rail

Pincer grab hanger and cable pull Standard transmission 4/1 (8/1 on request)

- Gripper with gripping jaws on frames with recessed grips.

- Pincer grippers with gripping jaws on frames with grip strips.

- Tong gripper hangers on frames with recessed grips

- Tong gripper hanger on frames with handle strips

All gripper types are also available without a cable pull.

Wire rope hoist with gear ratio 4/1

Operation of the backstop:

- Shift lever top: cable secured against release.

- Gearstick Lower: Ready to drain...

| Shift lever upwards ⇒ | Lift |

| Gearstick lever down ⇒ |

Drain position |

| Tighten briefly on the hauling rope ⇒. |

Release for draining |

Wire rope hoist

Our wire rope hoists are equipped with an easy-to-operate, switchable backstop. The clamping mechanism is designed for many lifting cycles and is very gentle on the rope.

The 6mm thick traction rope is made of a virtually stretch-free and very resilient sheathed Dyneema material.

Rope pull data:

- Components: cable hoist, drawbar with draw chains and scissor grabs.

- Translation: 4/1

- Lifting height: 1 metre

- Installation height: lower edge of running rail to lower edge of tension beam approx. 35cm.

- Housing / Mechanics: Stainless steel.

- Castors: High-strength aluminium, anodised surface, ball bearing.

Planning a roller track in the apiary:

- Variant 1: A single roller conveyor that directly above the hives. (Simple assembly. The distance between the top of the hive and the runner must be high enough to allow raised frames to pass over adjacent hives).

- Variant 2: Two roller conveyors, one mounted on the left and one on the right side of the room, with transverse roller conveyor. (Frames, optionally the whole hive, are lifted only slightly for transport and can then be transported or placed anywhere in the room).

We will be happy to advise you on the purchase and construction of a castor system for your individual needs.

Enquiry: Technical design of the track roller device

Videoclip:

Scissor grab hanger in practice, film 01/02

Download:

Customer video: Small crane system in the apiary.

Your individual bee house, construction and manufacture by Holzbau Reichl: http://holzbaureichl.de/